The Dispatch | Expert | Scudo Hub

Get help & share your Citroen Dispatch (Jumpy) | Peugeot Expert | Fiat Scudo tips

You are not logged in.

- Topics: Active | Unanswered

#1 Re: Maintenance » No warning beeps at all » 2025-09-16 15:21:38

I think that the sounds come from under the steering wheel. I can see what appears to be a speaker of some sort through the cowling.

Can't find any part numbers though.

#2 Re: Maintenance » Cant get rid of warning message on display » 2025-09-02 09:10:57

Normally you would need Lexia to reset the fluid level. I would expect that tooled up mobile mechanics could do this with their 3rd party readers.

#3 Re: General Discussion » Resistor to prevent airbag warning light when removing passenger seat » 2025-08-14 09:36:20

I used 2 x 0.125w 1ohm resistors, with a 2A fuse in series, so that any fault condition would blow the fuse rather than set the resistors on fire.

Once soldered up, covered it in insulation tape and tucked back under the mat.

Easy to get on eBay.

#4 Re: General Discussion » New key? » 2025-08-13 13:37:20

I bought a blank but original new key fob off eBay, thanks for the replies!

A new key fob for 2004? I'd be interested in seeing the listing

#5 Re: General Discussion » New key? » 2025-08-08 13:31:23

Worth checking the micro switches on the pcb, they are easily broken. You can always check if the RF is working with a cheap key fob tester, or a software defined radio setup (if you have the spare time).

Other than that you could buy an old keyfob/pcb off ebay eg https://www.ebay.co.uk/itm/396315200474 I always found it easier to look for C8 or Xantia fobs which are the same.

Lexia can be used to add the remote, but just be aware that you will need the 4 character alpha numeric code that came with the original van to access the key programming pages.

#6 Re: General Discussion » My expensive journey so far (2013 Citroen Dispatch Enterprise) » 2025-08-06 09:06:05

bncomps wrote:That's unlucky! I hope you manage to get the problem sorted sooner rather than later.

At a bit of a loss as to who to try. I will have to get it done before winter though.

Mechanics, like most things, aren't what they used to be.

I was in a similar situation, and eventually chose to go to the dealers. My thinking was that I could leverage off the manufacturers to get a resolution and I would refuse to take it back until it was fixed. Things got so bad that they started to screen out my calls, and several times I contacted to dealership head office to get things moving. Boy did they hate me.

Of course it was expensive to pay for the parts bingo, however I asked for a contribution from Peugeot, and got 25% off the bill, which was something.

#7 Re: General Discussion » My expensive journey so far (2013 Citroen Dispatch Enterprise) » 2025-08-02 15:02:08

Yes been there. I spent more in the first year on my 2015 2.0, that I spent on the MK1 the previous 5 years - and that included the cost of the van. Unfortunately I did not find out about the issue until the first trip to France after spending 3 months on the conversion. The same as you, I was seduced by the upgrades - 130BHP vs 70BHP, aircon, cruise control, (pseudo) AWD and the (tiny) extra clearance from the ground.

In my case the DPF was cracked due to 4 worn injectors clogging it up. This took the best part of a year to get fixed, including the useless dealer technician guessing all the way.

I would suggest that you get hold of something to monitor the DPF regens to avoid getting blocked. Try out FAPLITE in the Amazon App Store, to see if it supports your ECU, before paying for the full version.

#8 Re: Maintenance » Mk2 Scudo: Where is the AC clutch relay? » 2025-07-23 10:24:03

Thank you very much for the reply. Oh man, that is annoying. I wanted to test the relay before buying a new AC clutch... Oh well, Maybe it's possible to remove the relay with a soldering iron to test it?

I did see a guy on youtube bypass a relay with an external one.

https://www.youtube.com/watch?v=43vBiWbXM2s

#9 Re: Maintenance » Mk2 Scudo: Where is the AC clutch relay? » 2025-07-22 16:36:42

Hello, I have a 2007 Mk2 Fiat Scudo.

I am looking for the AC clutch relay. The under bonnet fuse box seems to have a second layer under the top layer of fuses, I can see some relays in there but it looks like a mission to split the fuse box, it's doesn't look like it was designed as a service access. Am I looking in the wrong place? Are the relays in the cabin fuse box passenger side? That's also difficult to access coz they are side on and I can't see what's in there!

I've had the AC re-gassed but then it still wasn't working and I realised the AC clutch isn't spinning. So I want to test if the AC relay's gone before splashing out on a new AC clutch.

Any pointers would be really helpful. Many thanks!!

The relays are not user serviceable - everything is soldered in, you have to replace the whole unit.

#10 Re: General Discussion » TYRE size » 2025-05-25 18:38:03

Hi all, after some advice and guidance is it legal and all things insurance to fit 215/60R16C on an MPV MK2 TIA

Well that's what I have, as per the label in the driver door frame. 2015 van.

#11 Re: General Discussion » ODB2 Extended PIDs » 2025-05-20 16:26:47

Hello, and thank you for sharing this. Would it be possible to get the header (ECU address) to enter in Torque in order to make these PIDs work? Thanks in advance!

I leave the header blank, and just use the PID eg 21CB8001

I suspect that the pids are unique to the management unit.

#12 Re: General Discussion » Seat Bases » 2025-05-18 19:08:59

My experience would suggest that the base acts as the adapter between the seat and the floor. So each seat will have a specific base sorry to say.

#13 Re: General Discussion » Dispatch 2007 central locking » 2025-05-10 18:23:07

The locks work with one polarity to lock, and the reverse to unlock. The colour of the wires is irrelevant, they are all numbered, if you can read the print. I would suggest trying to trace back from the doorframe contact points.

#14 Re: General Discussion » Nu Venture tyre pressure ? » 2025-05-03 18:24:22

There’s no tyre pressure sticker on the door frame

Look on the door itself.

#15 Re: General Discussion » HOW TO REMOVE JACK » 2025-05-02 18:24:22

This is my 2015 at the top.

#16 Re: General Discussion » HOW TO REMOVE JACK » 2025-05-02 16:38:43

At the very top of the jack is a knob that unscrews, and the jack will lift off

#17 General Discussion » Fuel filter shenanigans » 2025-03-24 16:49:50

- tee_cee

- Replies: 0

Really should not have being doing this today after overindulging at the weekend, but dropped a bolt into the bowels of the engine.

Got the endoscope out and amazingly found it within minutes about 30cm down. Took another 20 mins to get a hold of it.

#18 Re: General Discussion » To drive or not to drive » 2025-03-12 10:22:11

The optimist in me would say that it's only the last turn that is broken and the spring won't move in transit.

As it happens the AA guy seemed to think it was OK, and had been like that for a while, because the broken ends were rusted.

This despite the photo showing a clean end to the break and that there was a very loud ping when it went.

I wonder if the fact that he was running an hour late and had an hours travel to get home had an influence on this diagnosis.

So he suggested that I drive and he followed, which I refused several times, insisting that I was towed.

Another issue was that the transits that they use are now equipped to tow, rather than calling out a local truck. So I had to call the garage to check I could bring it in 2 days early.

#19 Re: General Discussion » To drive or not to drive » 2025-03-11 14:52:10

I guess the danger is that the broken bit shifts and falls off.

Breakdown is probably the way to go.

#20 General Discussion » To drive or not to drive » 2025-03-11 11:34:04

- tee_cee

- Replies: 6

So broken spring again. Any thoughts on driving the 2 miles to the garage?

#21 Re: Maintenance » Hand Brake Location » 2025-02-01 11:12:45

That 70's style toggle switch is hideous, which allows them to upsell a normal switch for £40

#22 Re: General Discussion » ODB2 Extended PIDs » 2025-01-06 17:06:01

Hi, my engine is DW10CD with DCM3.5BR2 ecu and I'm using diagbox v7.58

These are the PIDs and formulas that I've found, but I only really use the dpf related ones

Air Circuit

MP_REGIME_MOTEUR Engine speed 21C98001 INT16(A:B)

MP_DEBIT_AIR_MESURE measured air flow 21CA8001 INT16(AM:AN)

MP_CONSIGNE_DEBIT_AIR_a air flow setting 21CA8001 INT16(AK:AL)

MP_PRESSION_ATMOSPHERIQUE atmospheric pressure 21CA8001 INT16(K:J)

MP_CONSIGNE_PRESSION_TURBO turbo pressure reference value 21CA8001 INT16(G:H)

MP_PRESSION_TURBO_MESUREE turbo pressure measured 21CA8001 INT16(I:J)

MP_CONSIGNE_POSITION_TURBO turbo position reference value 21CA8001 M

MP_RECOPIE_POSITION_TURBO turbo position repeat 21CA8001 N

MP_RCOVANNETURBO Turbo pressure electrovalve open cycle ratio 21CA8001 AI

MP_CONSIGNE_POSITION_DOSEUR Mixer position reference value 21CA8001 Q

RECOPIE_POSITION_DOSEUR Mixer position repeat 21CA8001 R

RCOCDEDOSEUR Open Cycle Ratio for the air mixer electrovalve 21CA8001 ((AG:AF)-1000)/10

MP_CONSIGNE_POS_VANNE_EGR EGR valve position reference value 21CA8001 U

MP_RECOPIE_POSITION_VANNE_EGR EGR valve position repeat 21CA8001 V

MP_COMMANDE_EGR EGR valve control Opening Cyclic Ratio 21CA8001 ((W:X)-1000)/10

MP_CONSIGNE_POSITION_BYPASS_REFROIDISSEUR_EGR EGR exchanger Bypass position reference value 21CA8001 Y

RECOPIE_POSITION_BY_PASS_REFROIDISSEUR_EGR EGR exchanger Bypass position repeat 21CA8001 Z

MP_TEMP_CARB_C9 fuel temperature *1@\* 21C98001 AC-50

MP_TEMP_ADMI_DEBITMETRE air flow sensor air temperature 21CA8001 E-50

MP_TEMP_DEB Air temperature in the inlet manifold 21CA8001 F-50

Aircon

MP_REGIME_MOTEUR Engine speed 21CD8001 INT16(A:B)

MP_TEMPERATURE_EAU_b coolant temperature 21CD8001 D-50

MP_PRESSION_CIRCUIT_CLIMATISATION_a air conditioning circuit pressure@\* 21CD8001 K

MP_CONSIGNE_VITESSE_GVM_01 Fan speed *1 setting@\*1

MP_MESURE_VITESSE_GMV Measurement of the cooling fan speed

MP_CONSIGNE_VITESSE_GVM_02 Fan speed *1 setting@\*2

TENSION_CAPTEUR_NIVEAU_HUILE Oil level sensor voltage 21CD8001 N

Electrical

MP_REGIME_MOTEUR Engine speed 21C98001 INT16(A:B)

MP_TENSION_BATTERIE1 battery voltage 21CC8001 P/10

MP_CONSIGNE_DE_CHARGE_PROGRESSIVE_ALTERNATEUR_a alternator progressive charge reference value 21CC8001 N

TENSION_ALIMENTATION_5V_NUMERO_01 Supply voltage *1V n°*2@\*5@\*1 21CC8001 INT16(Q:R)

MP_COMMANDE_RELAIS_PUISSANCE power relay control

MP_ETATCDEDEM Starter control status

MP_ETAT_DEMANDE_DEMARREUR Status of the starting request

MP_COMMANDE_CHAUFFAGE_ADDITIONNEL_a Status of the additional heating control

Exhaust line

MP_REGIME_MOTEUR Engine speed 21C98001 INT16(A:B)

MP_ETAT_REGENERATION Status of the regeneration

MP_MASSE_TOTALE_SUIE_DANS_FAP total weight of soot in the PEF 21CB8001 INT16(J:K)/1000

MP_TEMPERATURE_FAP Particle emission filter temperature 21CB8001 INT16(Z:AA)

MP_PRESSION_DIFFERENTIELLE_FILTRE_A_PARTICULES difference in pressure between particulate emission filter input/output 21CB8001 INT16(P:Q)

MP_TEMP_ADMI_DEBITMETRE air flow sensor air temperature 21CA8001 E-50 possible 21cb8001 AH

MP_TEMP_DEB Air temperature in the inlet manifold 21CA8001 F-50

MP_DEMANDE_ACTIVATION_CONSOMMATEURS Power consuming equipment activation request 21CB8001 Bit 5&6 AB

VOLADDRESERVOIR Amount of additive in the additive tank 21CB8001 INT16(T:U)

NIVEAU_MINIMUM_ADDITIF_ATTEINT minimum level of additive reached

MP_VOLUME_TOTAL_ADDITIF_INJECTE Cumulative total additive weight in the particulate filter

MP_VOLUME_RESERVOIR_ADDITIF additive reservoir *1 volume@\* 21CB8001 INT16(R:S)

MP_DISTANCE_PARCOURUE_DEPUIS_ECHANGE_FAP distance travelled since particulate filter replacement 21CB8001 INT24(AI:AJ:AK)

MP_DISTANCE_PARCOURUE_DEPUIS_DERNIERE_REGENERATION distance travelled since the last regeneration 21CB8001 INT16(AC:AD)

DISTANCE_MOYENNE_ENTRE_LES_10_DERNIERES_REGENERATIONS average distance between the last *1 regenerations@\*10 21CB8001 INT16(AE:AF)

MP_DEGRE_ENCRASSEMENT_FAP_EN_SUIES degree of clogging of the PEF with soot

MP_DIST_AVANT_REMPL_FAP Distance remaining before replacement of the FAP 21CB8001 INT24(M:N:O)

MP_AUTORISATION_REGENERATION Authorisation of regeneration 21CB8001 Bit 5&6 AB

MP_CAPC_EFFEC_COURT_TERME Short term regeneration capacity

MP_CAPC_EFFEC_LONG_TERME Long term regeneration capacity 21CB8001 AH possible 21CA8001 E

CA_RICHESSE_CALCULEE_SONDE_A_OXYGENE mixture calculated by the O2 sensor 21CB8001 INT16(E:F)/1000

CHAUFFSONDEO2 Activation of the heating of the oxygen sensor

Fuel circuit

MP_REGIME_MOTEUR Engine speed 21C98001 INT16(A:B)

MP_DEBIT_INJECTE_MESURE measured injected flow 21C98001 INT16(O:P)/10

MP_SYNCHRONISATION_AAC_VILEBREQUIN camshaft/crankshaft synchronisation

MP_CONSIGNE_PRESSION_RAIL1 Setting for the fuel rail pressure 21C98001 INT16(K:L)/10

MP_PRESSION_CARBURANT_MESURE measured fuel pressure 21C98001 INT16(M:N)/10

MP_COURANT_REGULATEUR_DE_DEBIT_IMV Flow regulator current

MP_ETAT_ACTIVATION_STRATEGIES_CORRECTION_OUVERTURE_INJECTEUR injector opening correction strategies activation status

RCO_COMMANDE_REGULATION_DEBIT_CARBURANT Open cycle ratio controlling the regulation of the fuel flow 21C98001 J

MP_TEMPS_INJECTION_CYLINDRE_01 cylinder *1 injection time@\* 1 21C98001 INT16(AG:AH)/100

MP_TEMPS_INJECTION_CYLINDRE_03 cylinder *1 injection time@\* 3 21C98001 INT16(AI:AJ)/100

MP_TEMPS_INJECTION_CYLINDRE_04 cylinder *1 injection time@\* 4 21C98001 INT16(AK:AL)/100

MP_TEMPS_INJECTION_CYLINDRE_02 cylinder *1 injection time@\* 2 21C98001 INT16(AM:AN)/100

MP_TEMP_CARB_C9 fuel temperature *1@\* 21C98001 AC-50

MP_KILOMETRAGE_FIN_DERNIERE_BOUCLE_RECALAGE_PICL End mileage of the last PICL resetting loop 21C98001 INT24(CZ:DA:DB) pos 103

MP_CORRECTION_ACYCLISME_INJECTEUR_1 Correction of acyclism on injector *1@\*1 21C98001 INT16(DC:DD)-500

MP_CORRECTION_ACYCLISME_INJECTEUR_3 Correction of acyclism on injector *1@\*3 21C98001 INT16(DE:DF)-500

MP_CORRECTION_ACYCLISME_INJECTEUR_4 Correction of acyclism on injector *1@\*4 21C98001 INT16(DH:DH)-500

MP_CORRECTION_ACYCLISME_INJECTEUR_2 Correction of acyclism on injector *1@\*2 21C98001 INT16(DI:DJ)-500

MP_ECART_REGIME_MOTEUR_CYLINDRE_MOTEUR_1 Difference in engine speed on engine cylinder *1@\*1 21C98001 INT16(AU:AV)/16 -8000

MP_ECART_REGIME_MOTEUR_CYLINDRE_MOTEUR_3 Difference in engine speed on engine cylinder *1@\*3 21C98001 INT16(AW:AX)/16 -8000

MP_ECART_REGIME_MOTEUR_CYLINDRE_MOTEUR_4 Difference in engine speed on engine cylinder *1@\*4 21C98001 INT16(AY:AZ)/16 -8000

MP_ECART_REGIME_MOTEUR_CYLINDRE_MOTEUR_2 Difference in engine speed on engine cylinder *1@\*2 21C98001 INT16(BA:BB)/16 -8000

Immobiliser

PID 21C88001

MP_ETAT_VERROUILLAGE_DEVERROUILLAGE_CALCULTATEUR control unit condition

MP_ETAT_PROGRAMMATION_ANTI_DEMARRAGE status of the coded engine immobiliser programming

MP_PB_TRANSMISSION_CODE_DEVERROUILLAGE problems detected when transmitting the unlock code

Misc

MP_REGIME_MOTEUR Engine speed

MP_SYNCHRONISATION_AAC_VILEBREQUIN camshaft/crankshaft synchronisation 21C88001 F

MP_VITESSE_VEHICULE_a vehicle speed@\*

TENSION_SIGNAL_PEDALE_ACCELERATEUR_01 accelerator pedal signal voltage *1@\*1 21CC8001 INT16(E:F)

TENSION_SIGNAL_PEDALE_ACCELERATEUR_02 accelerator pedal signal voltage *1@\*2 21CC8001 INT16(G:H)

MP_POSITION_DE_PEDALE_ACCELERATEUR accelerator pedal position 21C98001 D

MP_INFO_POINT_DUR Accelerator pedal point of resistance information

MP_TYPE_BOITE Gearbox type

MP_RAPPORT_BOITE_DE_VITESSES gear ratio *1@\* 21CC8001 J 1-6 & 9

MP_ETAT_CAPTEUR_POINT_MORT Condition of the neutral sensor

MP_ETAT_CONTACTEUR_DE_FREIN_PRINCIPAL principal brake pedal

PEDALE_FREIN_REDONDANT redundant brake pedal

MP_VITESSE_CONSIGNE_REGULATION_DE_VITESSE Cruise control speed setting

MP_ETAT_REGULATION_VITESSE cruise control status

MP_VITESSE_CONSIGNE_LIMITATION_DE_VITESSE Speed limiter speed setting

MP_ETATLV speed limiter status

MP_ETAT_CONTACTEURS_FREIN_EMBRAYAGE Status of the limiting of the vehicle speed

MP_PEDALE_EMBRAYAGE clutch pedal 21CC8001 D

MP_VAL_POSITION_EMBRAYAGE Value of the clutch pedal position 21C78001 AB

MP_ETAT_MOTEUR *1 engine status@\* 21C78001 AC 21C88001

MP_MESURE_MANOCONTACT_PRESSION_HUILE oil pressure switch measurement 21CD8001 L

Battery - CAN DIAG bus

Battery current 21C0 (1000- INT24(C:D:E))/1000

Battery Voltage 21C0 (INT16(A:B)+3000)/1000

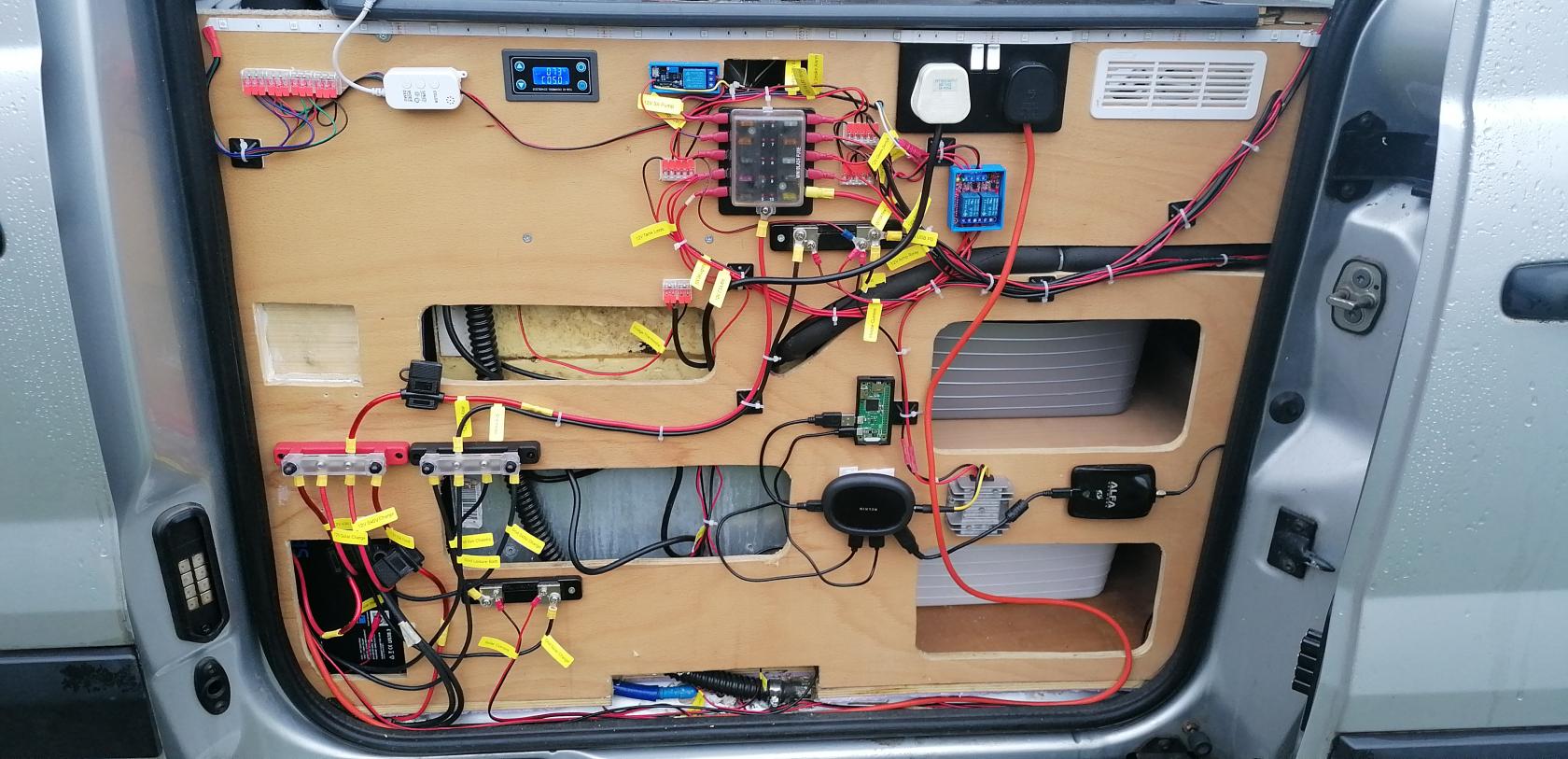

#23 Re: Camper Conversions » Storage opportunities » 2024-12-20 17:35:30

They were branded as Glowmaster https://www.groupon.co.uk/deals/glowmas … n-heater-1

But they are just cheap chinese ceramic heaters. I took the plug off and wired in a rf remote switch so I can power one or both. Got the Autoterm fitted a few months ago but kept the electric heaters anyway

#24 Re: Camper Conversions » Storage opportunities » 2024-12-20 11:56:40

I'm a big fan of making used of dead areas, however I reckon that tools etc. flying around the engine bay wasn't a great idea.

These are the spaces that I used on my MK3 (2015)

Behind passenger seat - Fogstar Drift Seat 230Ah on its side

Under passenger seat - 1kw inverter and 40A b2b charger

Under drivers seat - 2 x 500w heaters, Autoterm heater outlet

Under van - Autoterm heater

Spare wheel - 2 x 35l water tanks

Rear doors vertical storage

Side door vertical space for electrics

#25 Re: General Discussion » 2010 dispatch 1.6hdi 8v , turns over won't start . » 2024-11-02 23:21:39

I'm gona get a decent computer in it an go from there , my rib hips head an arms couldn't take anymore today ?

Feel like that every day now